Number 1 trimmer of Europe

For your cutting machine, visit us at Dutch Trimming Company

For those looking for a cutting machine with a powerful motor and easy operation, the DTC Pro has an excellent device in their hands. Dutch Trimming Company has done everything to perfect the power, efficiency and ease of use of this machine. With a one-year warranty and super-fast delivery of spare parts, you also get fantastic service.

DTC Pro, the cutting machine for a professional result

The DTC Pro is a professional high-speed shearing machine made from high-quality materials. Dutch Trimming Company has developed this device for you to process large quantities of product in a fast, safe, and above all sustainable way. The most important aspect that we have had in mind when designing this machine is minimal product loss.

Because this cutting machine, unlike its competitors, is made in Europe, it has a 220-volt connection, fast delivery is guaranteed and maintenance is easy to organize (warranty service within 24 hours).

Each machine is easy to move due to the compact dimensions (90 x 60 x 80 cm) and the weight (70 kg). The machine is supplied with a mobile leaf extractor with a strong 2 HP motor (also 220 volts), a dust bag, a waste bag and a 1 meter suction hose.

For technical instructions you can follow DTC on YouTube.

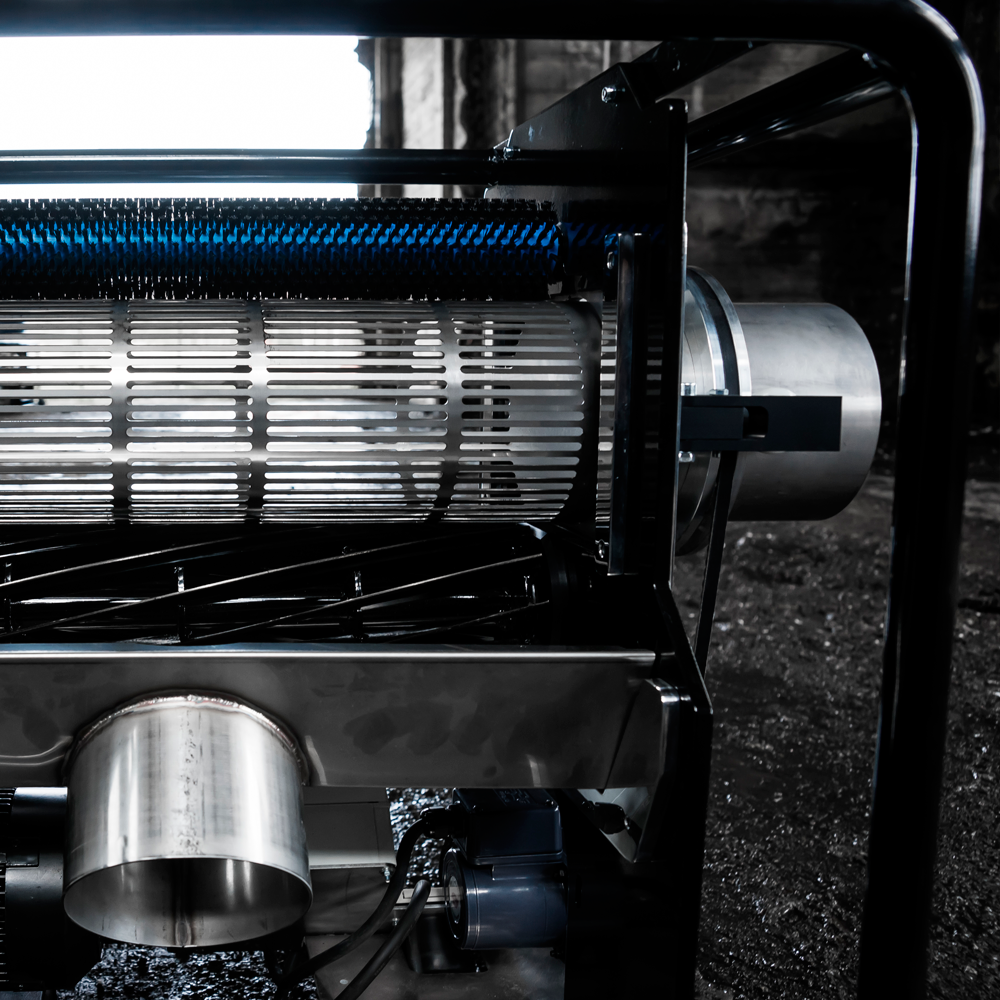

The drum of the DTX Pro

The drum of the DTC Pro is made of high-quality stainless steel with aluminum end pieces. A high cutting quality is guaranteed with a wall thickness of just 1 mm. This drum is height adjustable if desired.

Easy operation of the cutting machine

The liquid-tight electrical unit controls both knife and drum and is equipped with relays with jamming protection for optimum protection of the motors and a smooth running of the cutting process.

By means of the adjustment mechanism on both sides of the counter knife you can always adjust the sharpness. The mechanism is adjusted in the factory in such a way that the cage knife has a self-sharpening effect and only needs to be adjusted after approximately 50 turns.

Balanced cutting machine technology

The specially developed 11-fold cage knife is ball bearing mounted on both sides of the machine and balanced for vibration-free turning. Underneath is a stainless steel sump tray with extraction connection and an easy to dismantle lid. The stainless steel drum is self-cleaning by means of an industrial brush. The brush is also ball-bearing and rotates continuously.

Both AEG electric motors are of high quality and are controlled by a unit. All this is in a tubular frame coated with high gloss.

High Speed Drive of the cutting machine

The throughput speed of the product can be adjusted with adjustable feet on the supply side of the machine. With a double spirit level on the top of the spacious delivery bin, the throughput speed can be controlled.

For safety, the high-speed drive is behind a safety glass window. The drive is done by means of a V-belt.

The stainless steel drum runs freely in eight bearing-mounted rollers and can be easily removed without tools for cleaning. The drum is also driven by a non-slip V-belt.